DIGITAL TWINS

Alongside our digitizing and layout solutions, we enhance your projects with Prevu3D's visualization tools for the manufacturing industry.

3D Visualization Solutions

Based on the data collected, we create an intuitive, ultra-precise digital twin of your spaces and assets, facilitating their management and optimization.

-25%

Reduction in planning errors

-35%

Lower operating costs

+70%

Increase in collaboration

What is Prevu3D?

Prevu3Dis an all-in-one platform that uses reality capture data to create sophisticated 3D mesh models, offering the most realistic digital twin for manufacturing sites. Our solution is designed for sectors such as manufacturing, which handle high-value physical assets and require complex engineering designs, significant investment, and the approval of multiple technical and non-technical stakeholders.

Improve production management and transform your operations

Prevu3D helps companies use digital twins for facility planning and modernization. The rapid creation of iterations for viability assessment improves the decision-making process.

- Optimize plant layout.

- Faster changeover to increase productivity.

- Reduce training costs in skills and safety, contributing to a better working environment.

Key features

Centralize all your reality captures

Host, manage and process reality capture data. Visualize and share point clouds, convert them into 3D meshes and manage RealityPlan™ projects online.

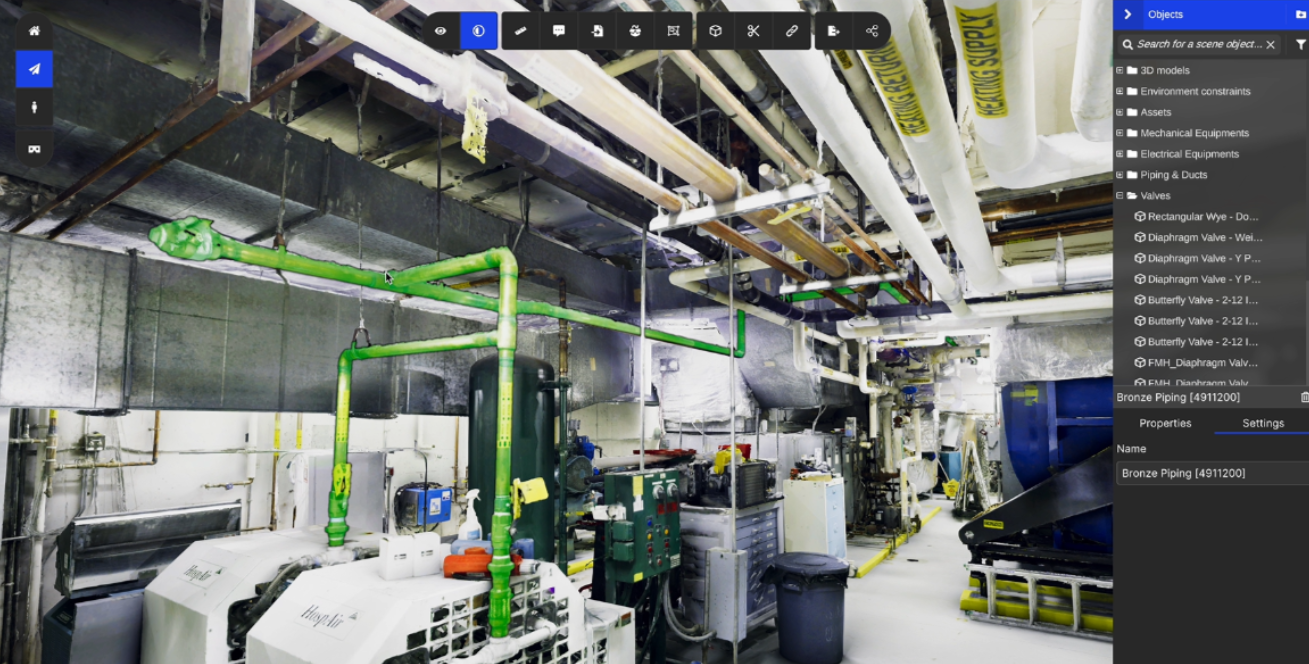

RealityAsset: Definition & features

Define complex manufacturing assets and add parameters linked to RealityAssets, such as inspection requirements, including frequency, accessibility and date of last inspection.

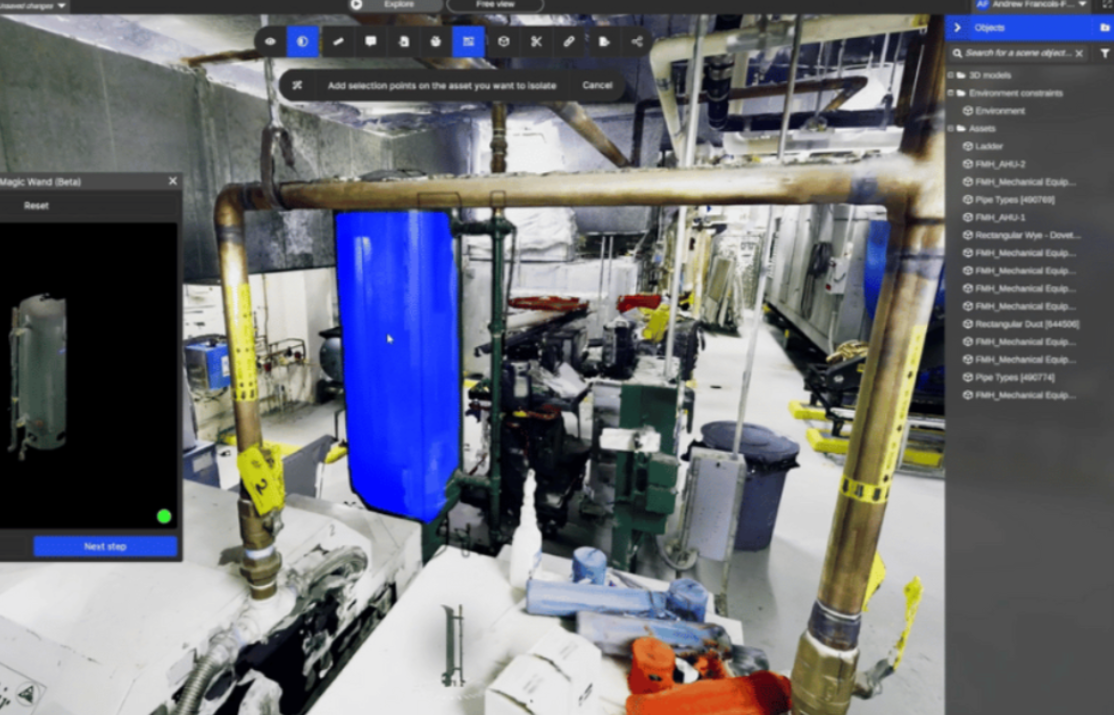

Design engineering tools

Discover our toolbox for iterating technical designs. Modify, create and share scenarios. Measure, move machines and check fit with ease.

MOST FREQUENT

QUESTIONS

Have questions or want to learn more about our solutions and services? Don’t hesitate to give us a call, our team will be happy to help!

Are virtual tours secure?

A digital twin is a virtual replica of a real space or physical asset. Digital twins reflect the current state of the asset and can be continuously updated with data from its physical counterpart. Digital twins can create simulations and predict future behavior, streamline collaboration and optimize operations.

What is a point cloud?

A point cloud is the raw material for a digital twin. Point clouds are created by running a 3D scanner back and forth over walls, pipes, equipment, vehicles and much more. The scanner head emits a laser beam or light with an optical spectrum and detects the reflection. The scanner measures the time and intensity of the reflection. It creates millions of points, each with a unique position and orientation in space. Multiple passes through a scanner create a dense point cloud, hence the name. Although raw point clouds are rich sources of information, they are too large to be used in a digital twin. Prevu3D transforms these raw point clouds into usable data.

What is a polygonal mesh?

Processing a point cloud using specialized software and hardware creates a polygonal mesh. The software creates lines to connect each point to its adjacent points, based on an analysis of each point's position and orientation. Adjacent points are connected by lines to form a set of small polygonal shapes. This array is a polygon mesh. The higher the density of the point cloud, the more surface detail appears on the mesh. Various data compression techniques can be applied to meshes to reduce the size of the mesh to content that users can interact with on wireless mobile devices, while preserving detail. Prevu3D has the best mesh solution on the market for digital twins.

PLATFORM

RealityPlan

Discover Prevu3D's all-in-one solution for hosting, managing and processing reality capture data. Easily visualize and share point clouds, convert them into 3D meshes and manage your RealityPlan™ design projects online.

DESKTOP APPLICATION

RealityPlatform

Go beyond visualizing and sharing 3D environments to accelerate engineering design and project collaboration. Discover the toolbox.